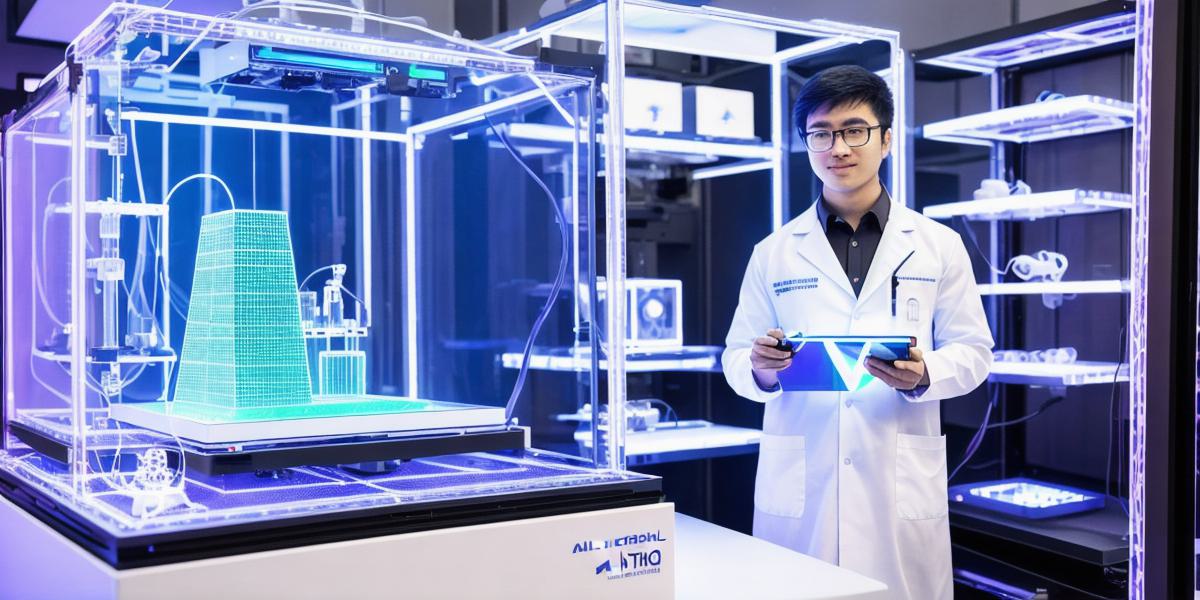

3D printing technology has revolutionized the way we design, manufacture, and even consume products. With the introduction of z-axis 3D printing, designers and manufacturers can take their creations to new heights by adding another dimension to their designs. In this article, we’ll explore how you can use z-axis 3D technology to revolutionize your designs and take your business to the next level.

What is Z-Axis 3D Printing?

Z-axis 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by laying down layers of material on top of each other until the desired object is formed. With traditional 3D printing, the layer of material is deposited in the x and y directions only, while z-axis printing adds an extra dimension by depositing material in the z direction. This allows for the creation of objects with complex geometries and features that would be impossible or extremely difficult to achieve through traditional manufacturing methods.

Benefits of Z-Axis 3D Printing

Z-axis 3D printing offers several benefits, including:

- Reduced production costs: With z-axis printing, you can create objects with complex geometries without the need for expensive tooling or cutting processes. This results in reduced production costs and faster time to market.

- Improved product quality: Z-axis 3D printing allows for precise control over every aspect of the manufacturing process, resulting in high-quality products that are consistent and reliable.

- Faster prototyping: With z-axis printing, you can quickly create prototypes of complex products, allowing for faster design iterations and more efficient product development.

- Reduced waste: Z-axis printing uses only the necessary amount of material to create an object, resulting in less waste and a more sustainable manufacturing process.

Real-Life Examples of Z-Axis 3D Printing

Here are some real-life examples of z-axis 3D printing in action:

- Medical devices: Z-axis 3D printing is used to create customized medical devices such as prosthetics, implants, and dental restorations. These devices can be tailored to the specific needs of individual patients, resulting in better outcomes and improved patient satisfaction.

- Aerospace: Z-axis 3D printing is used in the aerospace industry to create complex components for aircraft, spacecraft, and satellites. The technology allows for lightweight, strong, and durable components that are difficult or impossible to achieve through traditional manufacturing methods.

- Automotive: Z-axis 3D printing is used in the automotive industry to create customized components such as engine parts, fuel systems, and exhaust systems. These components can be tailored to the specific needs of individual vehicles, resulting in improved performance and reduced emissions.

- Architecture: Z-axis 3D printing is used in architecture to create complex geometries and structures that are difficult or impossible to achieve through traditional construction methods. The technology allows for more efficient and sustainable building practices.

How to Get Started with Z-Axis 3D Printing

Getting started with z-axis 3D printing can be daunting, but here are some steps to help you get started:

- Choose a printer: There are several types of z-axis 3D printers available on the market, including Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Digital Light Processing (DLP). Choose a printer that